DTH HAMMERS & BITS

Multi-Hammer Drill

Drill Hub Inc. & Strategic Partners

Multi-Hammer Drill

When drilling through rocks, conventional rock augers and buckets (and even core barrels) quickly lose their effectiveness as the strength of the rock begins to exceed 25 MPa.

HEMCO Multi-Hammer drills are a modern solution for drilling in hard rock formations and we have developed a highly effective Multi-Hammer for drilling 610mm to 1200mm boreholes in medium rocks as well as the hardest formations.

Description

Multi-Hammer Drill for 600mm to 1200mm Borehole

HEX connections for ease in assembly and disassembly.

Robust construction, yet lightweight.

Can work without shock absorber as vibrations are low.

Extension rods available for deeper drilling.

Working Principle

The drill employs three DTH hammers of 8" (200mm) with drill bits of 11" (275mm) diameter mounted on the lower end of the DTH hammers. The hammers work inside a steel barrel and the geometry of the arrangement is such that each drill bit extends about 1" (25mm) beyond the barrel.

Air is introduced through a swivel at the top of drill string and the air flow is distributed to each of the three DTH hammers through a distribution chamber at the top of the barrel.

As drilling proceeds, the cuttings are lifted upwards through the annulus between the borehole wall and the steel barrel and these cuttings settle into a collection barrel mounted on top of the drilling barrel.

Once the collection barrel becomes full, the drill is lifted out of the borehole and the collection barrel is pulled upwards by the auxiliary winch of the drilling rig to empty the cutting. Subsequently the drill is once again lowered into the borehole to proceed with the borehole drilling.

Drill pipe

The drill pipe comprises of a high strength tube with an 8" (200mm) HEX pin on one end and a corresponding HEX box on the other end. The length of the drill pipe can be adjusted as per job requirements. Also, additional tubes can be easily connected together to form longer drill strings

Air swivel

The air swivel has a robust structure which ensures long hours of trouble free drilling. The connection at top is a 4" x 4" box while the bottom comprises of 8" HEX box.

“Straight” Drilling

“Straight” drilling is very conveniently possible using any normal piling rig working with a standard telescoping kelly bar.

A kelly box of the required size is bolted onto the top of the hammer barrel and air is supplied through an inlet below the kelly box form where it is distributed to each individual DTH hammer through a distribution chamber at the top of the barrel.

As drilling proceeds utilizing 180 degree oscillatory motion of the kelly bar, the cutting are lifted upwards through the annulus between the borehole wall and the steel barrel and these cuttings settle into a collection barrel mounted on top of the drilling barrel.

Once the collection barrel becomes full, the drill is lifted out of the borehole and the collection barrel is pulled upwards by the auxiliary winch of the drilling rig to empty the cuttings.Alternatively, CFA drill string instead of kelly bar can be attached to top of the Multi-Hammer barrel through standard HEX joints. In this case, continuous drilling can be undertaken as the cuttings settle on the flights of the CFA.

Once drilling to the required depth is completed, the CFA is withdrawn and the cuttings cleared from the flights of the CFA.

Reverse Circulation Drilling (RCD)

RCD drilling when done in conjunction with the HEMCO Multi-Hammer is a very efficient method of boring through all types of formations.

This method is equally effective for both shallow drilling depths as well as depths exceeding 100m.

For RCD drilling with the Multi-Hammer, a special coupling is bolted to the top of the steel barrel which connects the barrel with the RCD drill string through a HEX connection.

The drill string comprises of a series of standard (but robust) RCD drill rods coupled together with HEX box and pin joints. The top of the drill string connects to the lower side of the drilling rig gearbox through a drive adapter while an air swivel sits on top of the gearbox.

Air is supplied to the inlet of the swivel through an air hose which connects on the other side to air compressors of adequate capacity and pressure.

Customized Geotechnical Solutions

down-the-hole hammers

DTH BITS

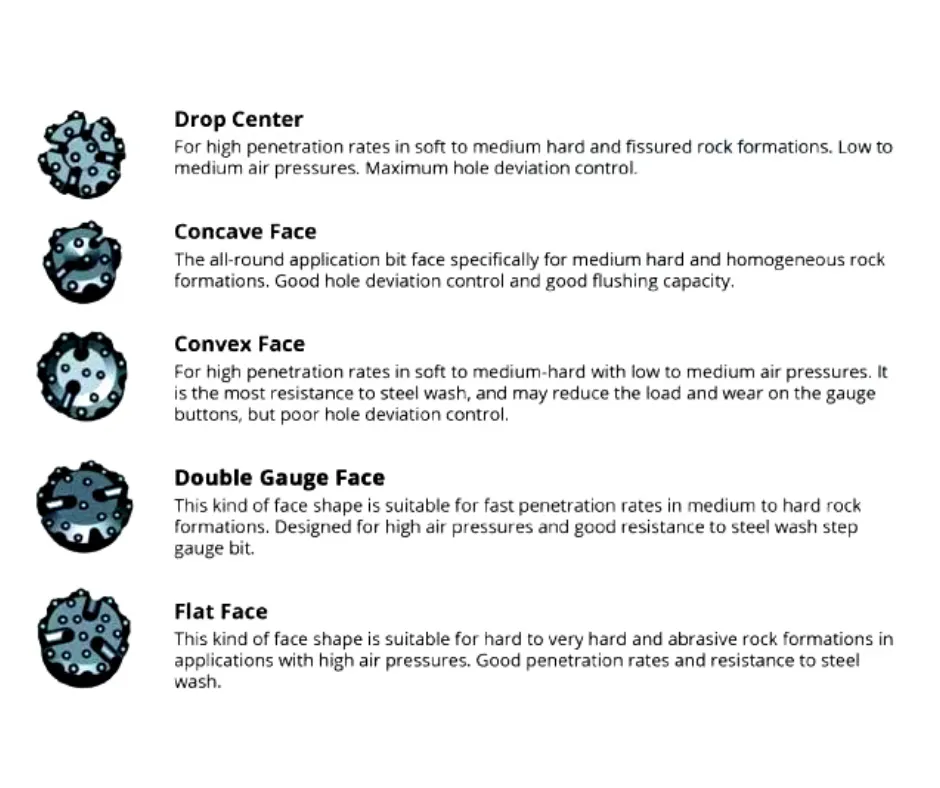

BIT FACE SHAPE

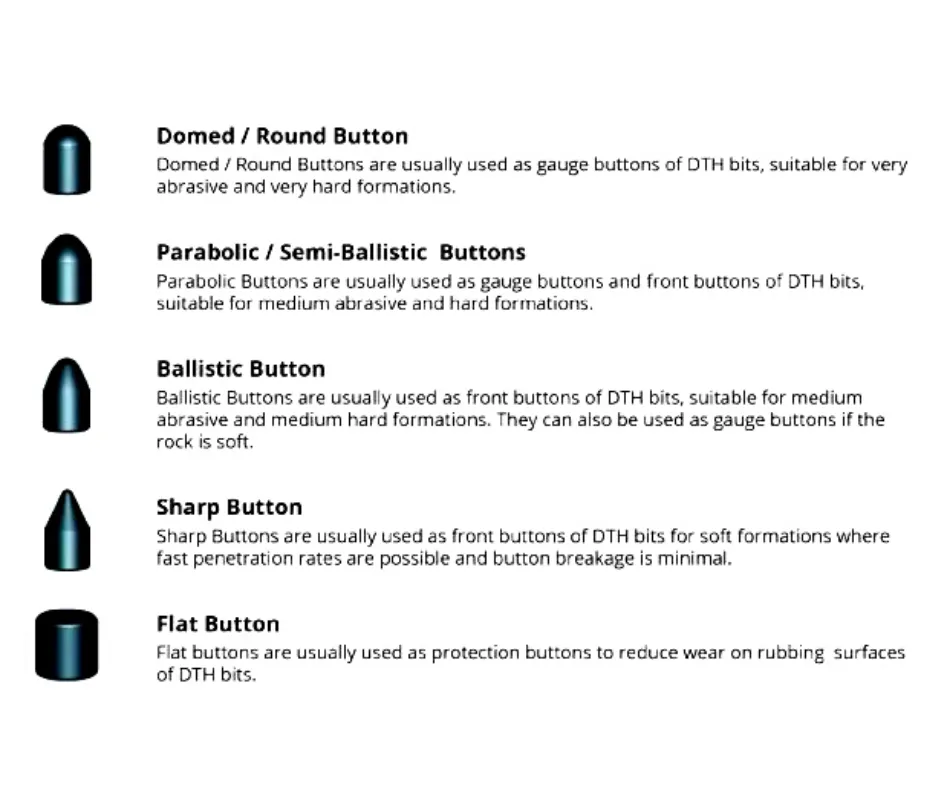

CABIDE BUTTON SHAPE

WHY CHOOSE US

Hassle Free Logistics

We will arrange all freight and

transportation of any equipment.

Wide Range Of Products

We offer a robust selection of Augers & Tooling, Casings, Teeth and Wear parts, DTH Hammers and Equipment.