ANCHORS

Hollow Bar Anchors

Applicable for various types of soil as well as for weathered rocks.

Hollow bar is used as drill rod, inner hole is used for flushing during drilling,

Once drilling is completed, inner hole serves for grouting of annulus.

Steel couplers are used to achieve required splicing length.

Speedy installation utilizing sacrificial drilling bit; drill rod becoming the rebar.

Ribs of fully threaded bar efficiently transfer stress between the bar and the grout.

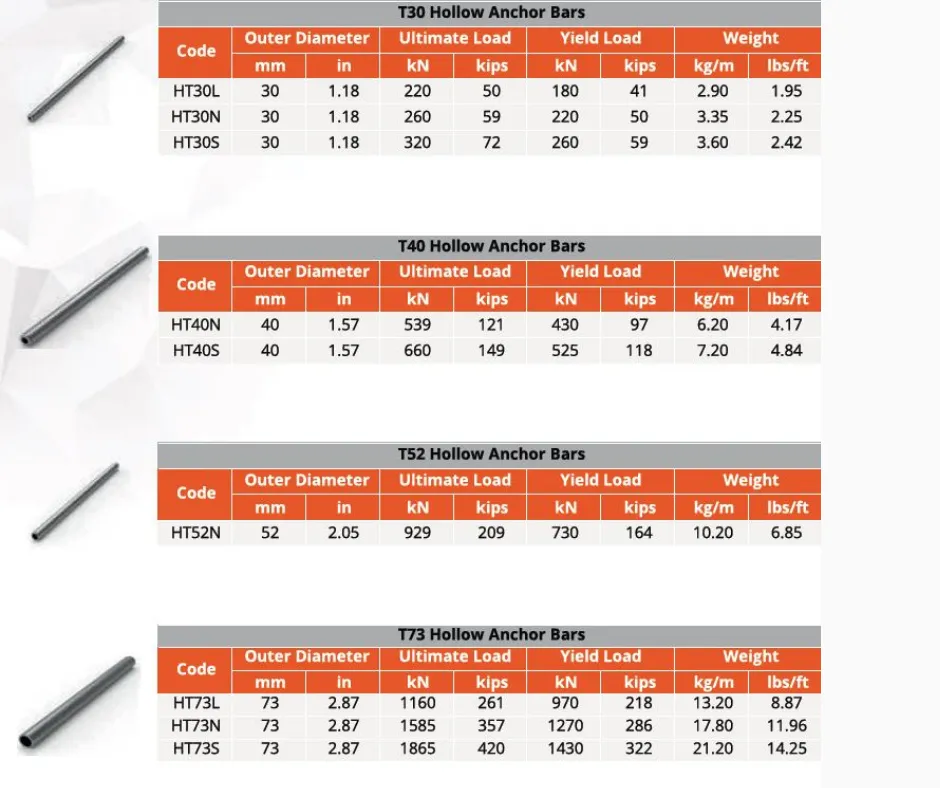

Self-Drilling Anchor bolt system is a combination of hollow anchor bar, coupler, nut, plate, centralizer and drill bit.

It can perform drilling, grouting and anchoring in a single operation. The hollow bar allows air

and water to pass freely through the bar during drilling to remove debris and then allow grout to be injected after drilling.

Grout fills the hollow bar and completely covers the entire bolt. Couplers are used to

join hollow bars and extend the bolt length while nuts and plates are used to provide the required tension.

Self-Drilling Anchor bolt system is safe, efficient and convenient.

It is suitable for broken rocks, loose soil and geological conditions where are difficult to drill the holes.

Applications

• Bridge Reinforcement

• Micropiling

• Retaining beam anchoring

• Slope Stabilization

• Tunneling

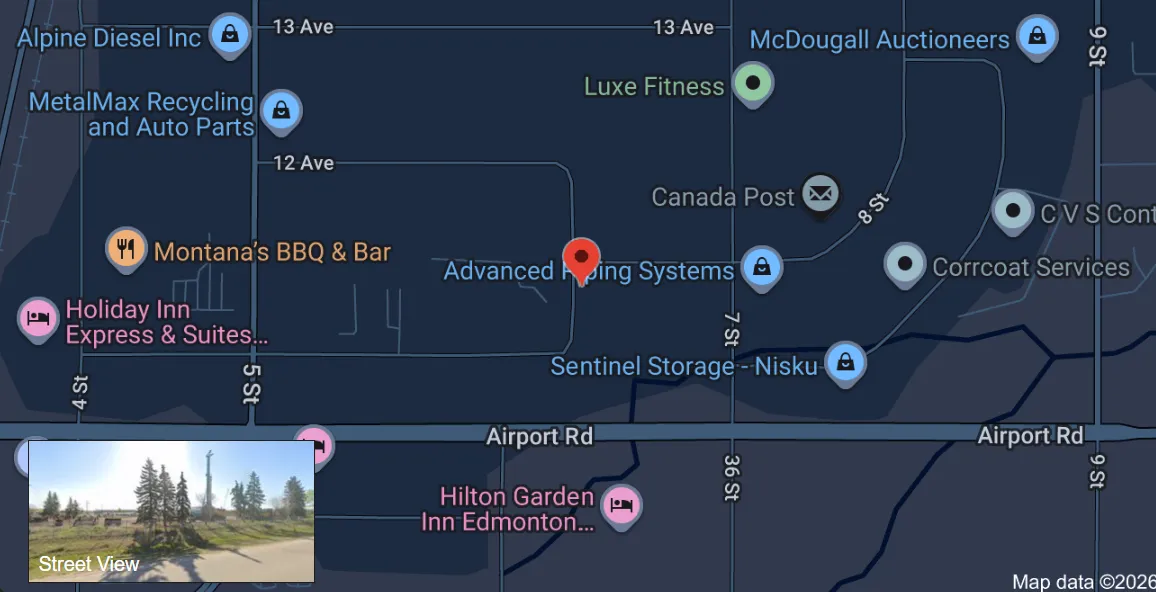

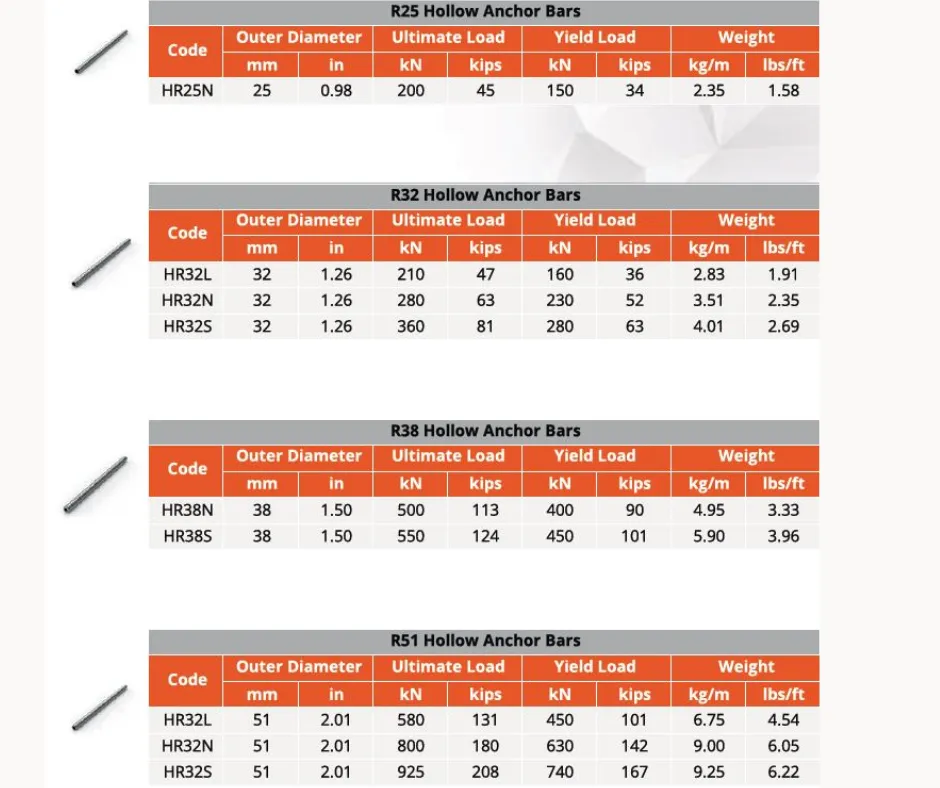

We supply these bars in two thread types, R-Type has a rope thread available from size R25 to R51. Similarly T-Type thread is as per international standard with sizes from T30 to T76.

Solid Bar Anchors

Active and passive anchors

Active anchors as those with a designed bonded and free length and subject to post tensioning after installation.

Passive anchors are fully grouted tension micropiles, subject to no post tensioning and are only “activated” when there is movement within the ground.

Temporary and permanent anchors

The main difference between temporary and permanent anchors are the design life of the system.

Temporary anchors are those with a service life of two years, longer than this is considered a permanent application.

The EN 1537 provides guidelines for the temporary corrosion protection of ground anchors and the EN 14199 for the temporary and permanent application of tension piles.

We offer high strength thread bar systems for different applications including Post Tensioning, Geotechnical, Rock Bolting,

Formworks, Underground works, Mining and Tunneling applications.

The strength of our threaded bar is in the rolling process, thread rolling deforms the blank material resulting in a stronger with minimal risk of fatigue relative to cut threads.

WHY CHOOSE US

Hassle Free Logistics

We will arrange all freight and

transportation of any equipment.

Wide Range Of Products

We offer a robust selection of Augers & Tooling, Casings, Teeth and Wear parts, DTH Hammers and Equipment.

WHY CHOOSE US

HASSLE FREE

LOGISTICS

We will arrange all freight and transportation of any equipment.

WIDE RANGE OF PRODUCTS

We offer a robust selection of Augers & Tooling, Casings, Teeth and Wear parts, DTH Hammers and Equipment.