SOLID & HOLLOW

STEM AUGERS

SOLID STEM

AUGERS

This method typically utilizes a Claw Bit to advance solid stem auger flights into the ground. The drilling equipment applies pressure against the top of the stem while turning it into the ground. The Claw Bit displaces the soil and moves it up the flights as the drill bores deeper in the subsurface lithology.

The advantages of Solid Stem drilling include the following:

Rapid drilling into soils with a lot of clay, which saves time and money.

It does not require circulation fluids, which makes site clean-up easier than some other drilling methods.

The project requires no casing materials in stable formations.

It allows for easy sampling in formations with a semi-consolidated soil.

The drilling can go down to 400 feet or more in semi-consolidated soils.

Solid stem is not appropriate for all conditions and it has certain disadvantages. It is not efficient in loose, sandy soil, especially at certain depths. It can only bore to a maximum width of 24 inches. It does not do well below the water table due to water infiltration.

HOLLOW STEM

AUGERS

This kind of drilling is like solid stem, except the Claw Bit is attached to a hollow stem, instead of a solid one. Once the bore hole reaches the desired depth, the hollow stem acts as a temporary casing, keeping the sides of the bore hole from caving in. The drilling crew can take samples through the hollow stem, or use it for setting a groundwater monitoring well into place.

The advantages of Hollow Stem Auger drilling include the following:

It allows for uncontaminated sampling in formations of unconsolidated soils.

Rapid drilling into clay-filled soils is easy and cost-effective.

Hollow stem auger drilling has disadvantages though. Drilling is not effective when boulders or large cobble stones are encountered. Also, auger refusal can occur when a large consolidated igneous formations are encountered. Its use is limited in loose, sandy soils where water table infiltration can contaminate sampling. Sampling in loose soils requires alternate sampling equipment like split spoon or continuous coring. The depth is limited to 150 feet or less.

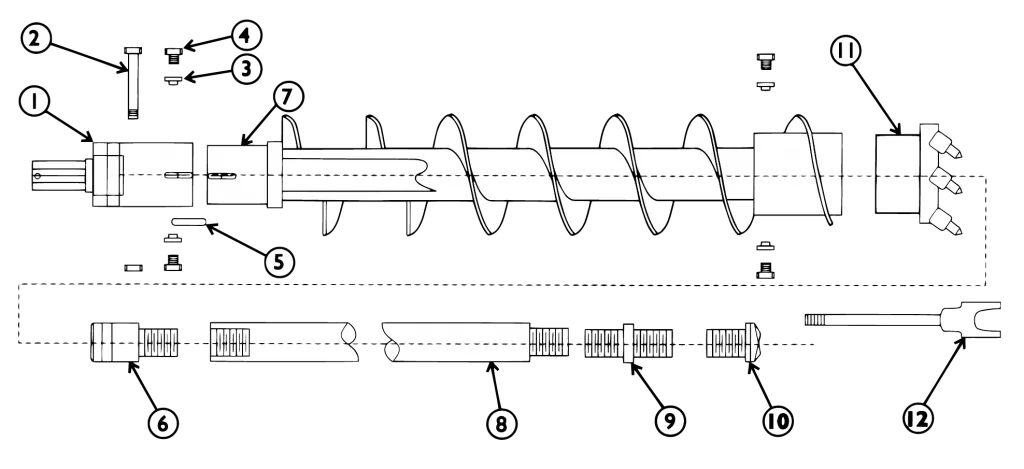

Drive cap

Nut and bolt for rod to cap adaptor

Bushing nut

Locknut

Drive key

Rod to cap adaptor

Hollow stem auger

Drill rod

Pilot bit connector

Pilot bit (Step type; Apex type; Bullet type)

11. Cutter head (Carbide blade; Spade blade; Blade bullet; Spade bullet; Bullet type)

Knock-out wrench for bullet cutters

WHY CHOOSE US

Hassle Free Logistics

We will arrange all freight and

transportation of any equipment.

Wide Range Of Products

We offer a robust selection of Augers & Tooling, Casings, Teeth and Wear parts, DTH Hammers and Equipment.